From Concept to Validation: What Comes Next in Our R&D Programme

January 2026

As we enter 2026, Network Stages moves into a crucial phase of its Innovate UK-funded research and development programme.

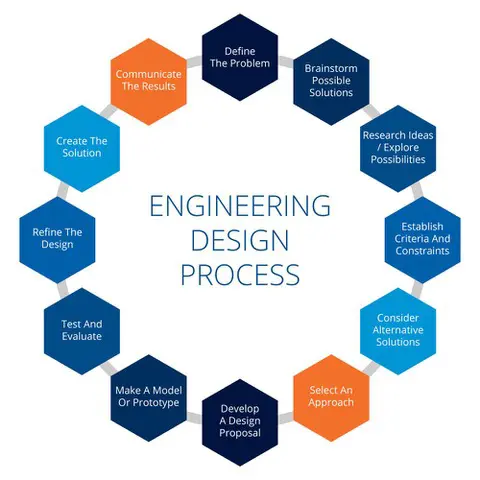

The early stages of the project focused on defining challenges, establishing performance targets and developing design concepts that could address long-standing limitations in temporary staging systems. With these foundations in place, the next phase is about validation.

Over the coming months, our R&D work will continue to concentrate on structural testing, component prototyping and performance verification. This includes validating load paths, assessing lateral stability, and ensuring that all core elements — decking, stairs, ramps and handrails — consistently achieve the target 7.5kN/m load capacity as well as an uprated 10kN system.

A key focus will be ensuring that performance improvements do not introduce complexity on site. Our objective remains clear: a system that is not only stronger and lighter, but simpler and safer to assemble. Individual handling, reduced build times and adaptable configurations remain central to every design decision.

Sustainability continues to underpin the programme. Material choices, component life cycles and transport efficiency are all being assessed alongside structural performance. By embedding these considerations into the design process now, we aim to deliver a system that supports both operational efficiency and long-term environmental responsibility.

2026 will also see continued collaboration with our partners to challenge assumptions and refine solutions. Engineering validation, real-world build scenarios and iterative testing will guide development, ensuring that the final system delivers genuine value to staging companies and clients alike.

This year marks the transition from concept to proof. We look forward to sharing further insights as testing progresses and designs evolve — and to demonstrating how disciplined R&D can reshape what's possible in temporary staging.

Collaboration, Learning and Momentum

December 2025

Innovation is rarely a straight line.

As Network Stages almost reaches the midpoint of our 18 month project, our Innovate UK-funded R&D project has become as much about learning and collaboration as it is about technical development.

While our ambition is clear — to deliver a next-generation modular staging system with increased load capacity, reduced weight and faster assembly — the route to achieving that goal has required careful planning, testing, discussion and adaptation.

One of the most valuable aspects of this project has been the collaborative approach. Working alongside our technical partners, Serious Stages and Cundall Engineering Consultants, has brought rigorous challenge and validation to every stage of development. Design assumptions are tested, calculations are interrogated, and practical build considerations are continually fed back into the engineering process.

This collaboration ensures that what we develop isn't just theoretically sound, but commercially viable and practical in real-world event environments.

Alongside the technical work, the Innovate UK framework has introduced a level of structure and accountability that goes beyond day-to-day commercial projects. Quarterly milestones, evidence-based reporting and clear work packages have encouraged disciplined progress and long-term thinking.

There have been challenges — learning new systems, refining documentation processes and balancing R&D activity with live project delivery — but these have strengthened our internal processes and sharpened our focus.

As the year draws to a close, we're proud of the foundations laid so far. Materials assessments are progressing, component concepts are being refined, and early design decisions are being validated against performance, safety and sustainability criteria.

2025 has been a year of groundwork, learning and alignment. The real excitement lies in how this momentum carries into the next phase of testing and development in 2026.

Our Innovate UK Journey

November 2025

Innovation starts with recognising persistent and common industry challenges.

Network Stages' Innovate UK journey began with a desire to eliminate long‑standing compromises in temporary staging systems. This stemmed from decades of experience working with industry systems that delivered to a point, but had clear limitations. What if Network Stages could lift those boundaries and could create a system so versatile, that almost anything was possible?

The application process required a clearly defined problem, a technically credible solution, and measurable industry and environmental benefits. There was a lot of paperwork, meetings and discussions, that led us to a comprehensive application that was submitted after a 4 month period.

Our proposal outlined ambitious but achievable improvements in load capacity, assembly efficiency and sustainability.

Collaboration was key, so from the outset, we secured two partners to strengthen engineering validation and practical relevance – Serious Stages Ltd and Cundall Engineering Consultants. We're so fortunate to have the expertise, support and guidance from these global giants.

Once the application was submitted, we waited two months not knowing what to expect. Out of nowhere at the end of January, we were advised we were one of 44 companies that were successful out of 2,134 applicants. There were still documents to formalise before the grant was confirmed and the process commenced on 1st May 2025.

The project then moved into structured delivery with defined work packages, quarterly reporting and rigorous evidence requirements.

The grant formalities, the communication structure and the required R&D work evidence that is needed to be uploaded onto the Innovate portal has been a steep learning curve. We appreciated the importance of building a relationship with our Innovate Monitoring Officer and continue to this day, reinforcing that communication chain.

In summary, the Innovate UK framework has provided discipline, focus and accountability, enabling long‑term innovation beyond commercial constraints.

For businesses considering Innovate UK funding, the process is very demanding but also rewarding.

We at Network Stages feel proud to share both our technical progress and our innovation journey as the project continues.

Testing Smarter, Building Greener : The sustainability ethos behind the scenes

October 2025

With the goal of reimagining the future of modular and temporary staging systems for live events and more, Network Stages Ltd. is pleased to announce the start of a significant research and development initiative funded by an Innovative UK grant.

With growing pressure on the events industries to reduce carbon emissions, sustainability isn't a choice. It's an expectation.

When it comes to our R&D testing, it's important to review Material performance V Environmental impact. Our aim isn't just to design and build stages - it's to build smarter, cleaner systems for the future. We want to develop next-generation temporary staging and decking systems — designed for performance, safety and sustainability.

Temporary structures, can have particularly high waste generation at the dismantling stage if single use components are not designed for reuse. Whilst official data for the UK temporary structures sector is scarce, the wider events industry is estimated to generate over 100,000 tonnes of waste each year destined for landfill or incineration!

Our R&D is targeting a reduction of that wastage by designing for reuse, refurbishing components and minimising single-use items. Our lighter and more compact design will enable a 50% reduction in the number of staging transport trucks required and its lighter weight will reduce CO2 emissions per km by up to 85% compared to conventional systems.

As part of this commitment, we will use 100%-recycled LM25 aluminium in production, and all our component materials will be industrially recyclable, minimising the environmental impact of manufacture.

This work is not only supported by Innovate UK but is in collaboration with our technical partners, Cundall and Serious Stages. Together, we're developing a next generation modular system aligns with the UK's Net Zero 2050 goals.

Over the coming months, we'll be sharing more insights from our materials testing and design validation. We would love to connect with organisations who share our sustainability values and are exploring greener approaches to temporary builds.

Contact: loumarshall@networkstages.co.uk

Advancing Modular Staging Technology

September 2025

With the goal of reimagining the future of modular and temporary staging systems for live events and more, Network Stages Ltd. is pleased to announce the start of a significant research and development initiative funded by an Innovative UK grant.

Network Stages has come up with achievable and cost effective solutions which we are applying to our new system.

It is well known that Scaffolding-based temporary staging is complex and time-consuming to assemble, and to bear loads greater than 7.5kN/m, it often requires expensive bespoke scaffolding plans.

Temporary staging using prebuilt decking modules are cheaper and quicker to assemble, but can hold lower loads (5-7kN/m.) than scaffolding staging, and the decking modules take up large amounts of space during storage and transportation.

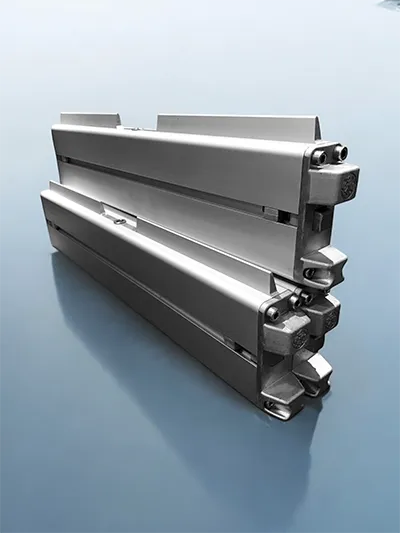

So our aim is to create a fully modular temporary staging system that will resolve the issues with both staging systems, featuring proprietary connections to achieve a load-bearing capacity of 10kN/m.

Our system will significantly reduce assembly time by 40-60%, total weight by 75%, and the space required for transportation and setup by 33-50%, compared to current staging solutions.

In addition, we will develop several key components to address common technical challenges in the industry, which are often solved through on-site improvisation or costly custom scaffolding. These components include:

- A stair and ramp system that supports the same load as flat decking (target: 10kN/m.)

- A "connect-anywhere" modular handrail for more flexible stage configurations.

- Adaptors that allow our system to integrate with existing scaffolding solutions.

- A safety-rated rigging system to enable secure connection of equipment (e.g. Audio cabinets, screens, scenery) directly onto the frame of the stage.

To be able to achieve the 10kN/m. load-bearing capacity, we will design sliding knee braces to reduce lateral movement and distribute weight more effectively. These will also allow for under stage storage minimising obstructions during assembly and disassembly.

Our design will allow individual workers to carry and assemble components without assistance, making stage construction faster, safer, and more efficient, benefiting both staging companies and clients.

By ensuring that the stage, stairs, and ramps can all support 10kN/m, we also eliminate the need for additional reinforcement when using heavy machinery such as forklifts. This further reduces the time and cost of assembling stages, particularly in industries like film and television, beyond the 40-60% time savings our system already offers.

Our R&D project will run for a period of 18 months with quarterly reporting ensuring our project targets are met. To keep up to date on our developments as we progress, follow our monthly blog!